Sulfur Oxidation

(mCPBA)

Examples:

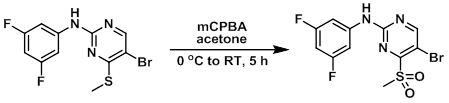

Example 1

The SM (1 g, 3 mmol) was suspended in acetone (10 mL), cooled to 0 C, and treated portionwise with mCPBA (2.59 g, 15 mmol). The suspension became a clear solution after stirring at 0 C for 30 min. The reaction mixture was then allowed to warm up slowly to RT and was stirred for 5 h. Saturated aq NaHCO3 (50 mL) was added to give a mixture with pH 8. The resulting mixture was extracted with EtOAc (3 x 10 mL). The combined organics were washed with brine, dried (Na2SO4), and concentrated to provide crude product. [1 g]

[Patent Reference: WO2010038081, page 120, ![]() (33.8 MB)]

(33.8 MB)]

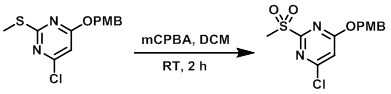

Example 2

To a solution of the SM (75 g, 253 mmol) in DCM (750 mL) was added mCPBA (130 g, 760 mmol) and the mixture was stirred at RT for 2 h. The reaction was quenched with sat NaHCO3 and extracted with DCM. The combined organics were dried (Na2SO4), concentrated, and purified by silica gel chromatography (eluting with 12% EtOAc/petroleum ether) to provide the product as a white solid. [75 g, 90.3%]

[Patent Reference: WO2012129338, page 254, ![]() (12.0 MB)]

(12.0 MB)]

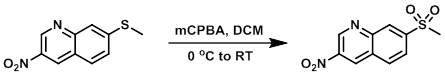

Example 3

To solution of the SM (141 mg, 0.6 mmol) in DCM (6 mL) at 0 C was added mCPBA (221 mg, 1.3 mmol) in DCM (3 mL). After warming to RT a white precipitate formed. The solids were filtered and rinsed with DCM (10 mL) to provide pure product. [85 mg, 53%]

[Patent Reference: WO2007084786, page 113, ![]() (9.4 MB)]

(9.4 MB)]

Example 4

To a solution of mCPBA (70%, 59.9 g, 304 mmol) in DCM (350 mL) was added dropwise a solution of the SM (28.8 g, 112.43 mmol) in DCM (400 mL). The reaction mixture was stirred at RT for 4 h. The mixture was washed with 0.5M NaOH (2 x 100 mL), brine, dried (Na2SO4), and concentrated. The crude material was purified by flash chromatography (0-20% DCM/heptane) to provide the product as a white solid. [29.3 g, 90%]

[Patent Reference: WO2016001341, page 83, ![]() (9.1 MB)]

(9.1 MB)]

Example 5

To a solution of the SM (2.38 g, 9.29 mmol) in DCM (25 mL) was added dropwise a solution of mCPBA (77%, 2.08 g, 9.29 mmol) in DCM (25 mL). The reaction mixture was stirred at RT for 30 min. The mixture was washed with 0.2M NaOH (40 mL) and the layers were separated. The aq layer was further extracted with DCM (50 mL). The combined organics were washed with 0.2M NaOH (40 mL), H2O (30 mL), brine (30 mL), dried (MgSO4), and concentrated. The crude material was purified by flash chromatography (0-100% DCM/heptane, then 0-20% MeOH/DCM) to provide the product. [2.06 g, 81%]

[Patent Reference: WO2016001341, page 101, ![]() (9.1 MB)]

(9.1 MB)]